How to keep your Pallet Racking Safe and Certified?

Written by D&C Storage Solutions | Published 4 years ago

Do you have a pallet racking system in your warehouse that meets Australian legislation requirements (AS 4084-2012). As a business owner it should be your top priority to keep it safe and certified. Safe and certified racking system can help you provide safe work environment, avoid unnecessary accidents and capital damages.

Here we have listed 8 rules that helps you keep your pallet racking safe and certified.

Correct installation

Most pallet racking safety issues arise due to poor installation. To avoid or minimize the risks of unnecessary accidents in future, always use professional pallet racking installers to install your racking. You should make sure that it is installed correctly and is safe to use.

Following Australian standard

Installation of pallet racking system must follow the procedures set by Australian standards. Australian Standard for steel storage racking AS 4084-2012 outlines the standard procedures that must be followed by pallet racking installers. It is advised to get your racking installation done by the pallet racking professionals near you.

Regular inspection

Pallet racks are made of high quality steel so they are strong and last for years. However they surely need regular checkup, inspection and maintenance. You should perform regular checkup on your pallet racking to make sure there are no immediate or future safety risks. If you fail to maintain the safety of your racking system, you might have to deal with unnecessary damages and accidents.

Record keeping

You can record the condition of your racking system during the regular inventory and stocktake. In most cases, racks get damaged due to getting hit by forklifts. Overloading beyond racking capacity is another factor that causes racking damages.

Auditing and certification

You should perform auditing and certification on your pallet racking at least once a year so that it meets Australian Standard for steel storage racking AS 4084-2012. Whenever there are accidents or damages, call your local Pallet racking experts for inspection and repairs.

Staff training

Storing and removing materials on pallet racking should follow a set of rules. Most of the pallet racking accidents and damages happen due incorrect placement of materials and overloading. As a business owner, it is your responsibility to train your staffs on how to use pallet racking the right way.

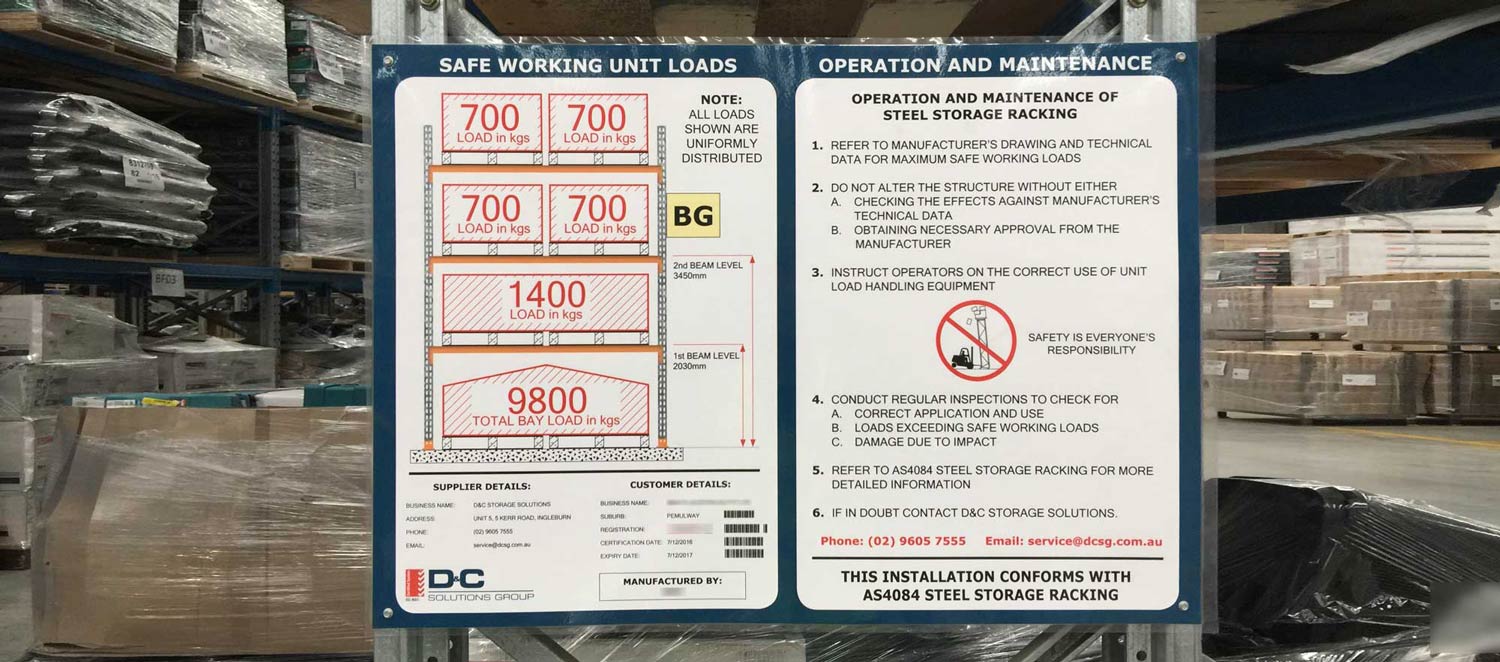

Clearly visible load signs

Make sure your workplace have clearly visible load signs in place with instructions and loading capacity.

Training forklift operators

Train your forklift operators to property handle materials in and out of pallet racking. Most of the pallet racking damages are caused by forklifts hitting the racking system.